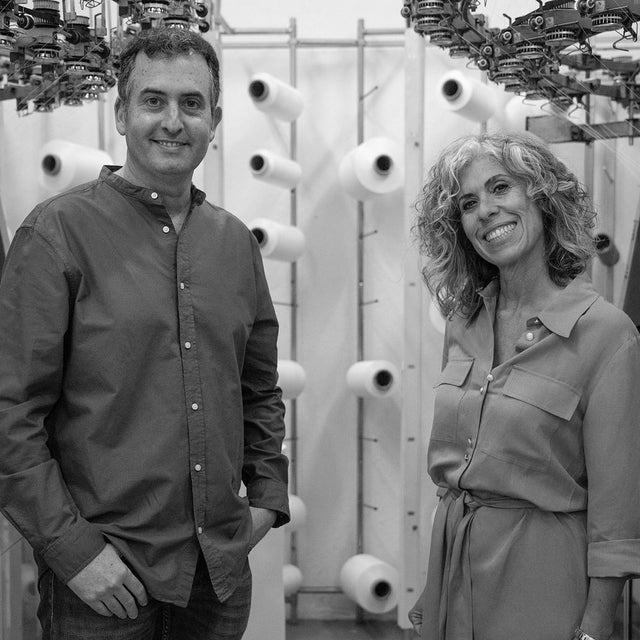

WELCOME TO OUR HOUSE!

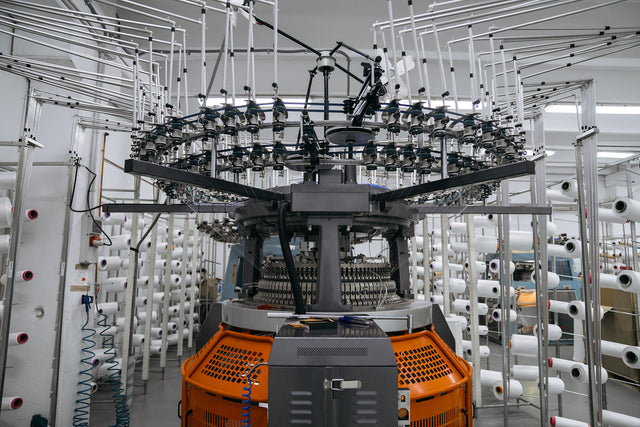

We are proud to say that we are local manufacturers. Artisans who work in their own factory with their own people and their own processes.

ORIGIN · SUSTAINABILITY · DESIGN

HOW DO WE DO IT?

STEP 2: DESIGNING

STEP 2: DESIGNING STEP 3: PRINTING

STEP 3: PRINTING STEP 5: SUBLIMATING

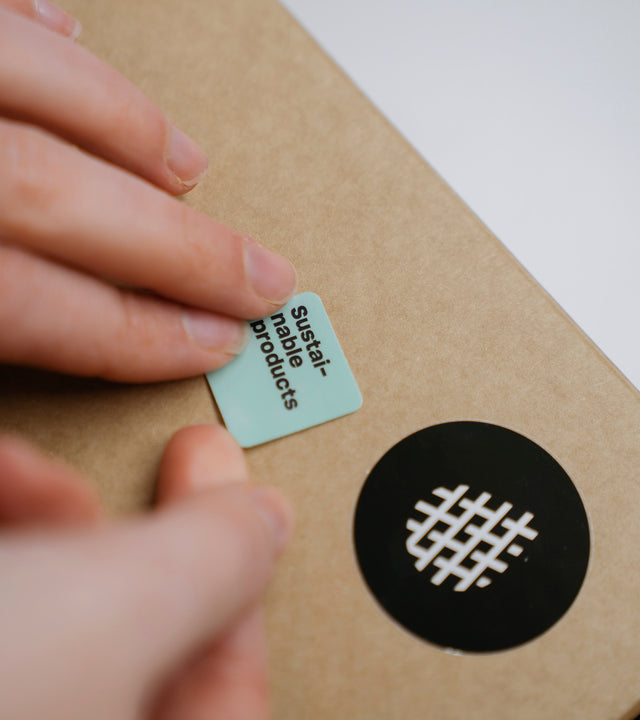

STEP 5: SUBLIMATING STEP 7: FOLDING & PACKING

STEP 7: FOLDING & PACKING