HOW DO WE CONTRIBUTE TO A MORE SUSTAINABLE TEXTILE INDUSTRY?

At Arpe, we trust in a responsible and conscious industry.

We know the only way of moving forward, as a company and as individuals, is by taking care of our actions and impacts. Socially, environmentally, and economically. And we can (and want to) do our part, especially where it affects us the most: the textile industry.

To be straight-forward, any industry in the world has an impact on the planet and the people. The simple act of producing and consuming, no matter how or where, has an effect. And the textile industry is no exception. However, we are in charge of what kind of impact we have. We believe we can be responsible and conscious with our actions, processes, materials and people. We believe that there is a “healthier” way to produce and consume that avoids “overdoings,” excesses and exploitations. It is just a matter of wanting to change things, for the better, for our future.

We use materials with as much recycled content as possible, finding the perfect balance that still assures high quality. Recycled materials are a little "worn-out," so using 100% of those would create less quality products, less absorbtion. Over the years, when it comes to our microfiber towels, we have increased the rPET content from 10% to 30%.

WE USE RECYCLED MATERIALS

It is very important to increase the amount of recycling in our products but, what’s even more important, is to reduce the amount of materials we use overall. We tend to believe that “more fabric means more quality,” just because of how it feels. However, our towels are 200 grams lighter than cotton towels, and they are tested and proven to dry 3 times their weight.

WE USE THE LEAST AMOUNT OF MATERIALS

In our B2B side of the company, our sustainable promotional products branch, we offer products created with our own waste. For example, our textile sleeves are made from leftover pieces of fabric and our pillow fillings (for a new prototype we are working on) are made from shredded fabric waste.

WE USE OUR LEFTOVER FABRIC

An exercise we have conducted and applied in our factory to investigate how we can create the least amount of waste. We find the most optimal sizes for our products and cut the fabric accordingly, we make more use of patterns and fabrics, we reuse our waste.

WE ECODESIGN

“To be recycled but also recyclable,” that’s how we want our products to be, making it easier for people to recycle them at the end of their useful life. That is, the majority of our products are made from 100% polyester. This way they can be thrown away all together, without having to tear them apart.

WE CREATE MONOMATERIAL PRODUCTS

If you don't have information about where your impacts come from, you cannot change them. Knowing the effects of designing, manufacturing, distributing, using and recycling. From the first idea to the end of the product’s life. And once you know that, you can start reducing them. And this is what we are working on now.

WE CALCULATED OUR CARBON FOOTPRINT

One of the main issues in the textile industry is our overconsumption, constantly buying a lot of things. This is why we seek for durability, creating meaningful products that last, that only need to be bought once. And we have tested them to know for sure. So, yes, our towels can last up to 9 years.

WE CREATE LONG-LASTING PRODUCTS

Our GRS certificate verifies the recycled content of our products and the responsible social, environmental and chemical practices in our production. The STANDARD 100 by OEKO-TEX is a worldwide eco-label that guarantees the inks we digitally print with are free of harmful substances for the planet and the people.

WE ARE CERTIFIED

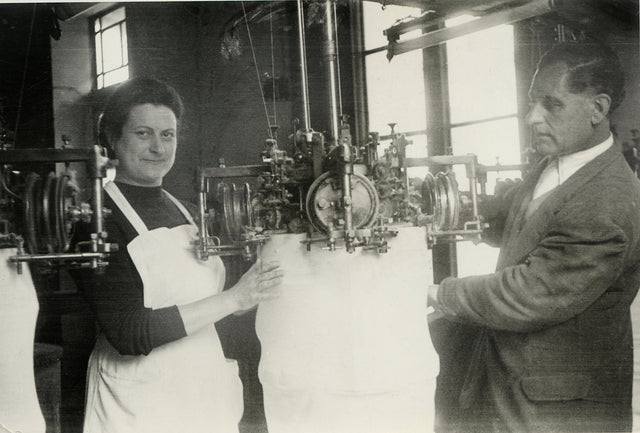

We manufacture in our own factory in Arenys de Munt, we are 20 amazing humans that live in the towns nearby. Everything we can do, we do it in-house. And what we cannot do, we look for in businesses nearby, promoting km0 production and enriching the local economy.

WE BET ON LOCAL PRODUCTION & ARTISANS

We are firm believers that quality is way more important than quantity. Being able to produce durable and meaningful products that will accompany you for years and years. in fact, our towels are tested to last about 9 years.

WE WORK IN SMALL PRODUCTIONS